ABB is one of the world leaders in electrical engineering. ABB employs 220,000 people in 1,150 companies operating in 140 countries. The main business segments are: power plants, power transmission, power distribution, transportation, environmental and industrial control.

ABB Process Automation, one of the ABB companies, is a leading supplier of industrial automation systems,

products and services. The company strives to deliver the highest level of customer value. In serving its customers, ABB combines industry-leading technology and cost effective, industry-specific application knowledge with

an uncompromising commitment to quality.

Advant Technology is at the heart of automation systems such as the ABB-MOD-300 and the ABB-Master System. Both systems integrate the essential hardware and software components to meet the demanding real time industrial requirements of process plant operations.

The ABB MOD 300 System is used for process monitoring and control in a variety of industries, including: pharmaceutical, chemical,

pulp and paper, metals, refining, mining and waste water treatment.

One of the reasons that ABB has been so successful in such a diverse variety of businesses is the integration of SL-GMS software in the Advant Station 500 Series for the ABB MOD 300 and ABB-Master System. SL-GMS software to provide the basic graphics engine and real time dynamic display support.

ABB adds customized user information and additional libraries of symbols which make AdvaCommand a unique ABB product. The SL-GMS dynamic graphic develop ment tool is so flexible that ABB is able to provide each application with an interface that utilizes the symbols and displays unique to the customer’s industry.

Advant Technology provides a fully expandable and upgradeable automation platform. The system consists of several elements. Bar code readers, weight scales, temperature and pressure sensors, recorders and other devices required by the application, are linked to controllers. The controllers in turn are connected to operator control units via a distributed communications network (DCN), a high-speed token passing ring modeled after the IEEE 802.5 standard. The system includes four software packages: AdvaCommand, Advainform, AdvaBuild and Batch 300.

The Advant Technology appmach U8es open systems standards such as UNIX, X Windows, TCP/IP, OSF Motif and SQL database access. SL-GMS software provides monitor and control functions distributed both function ally and geographically on a one-to-one real-time basis.

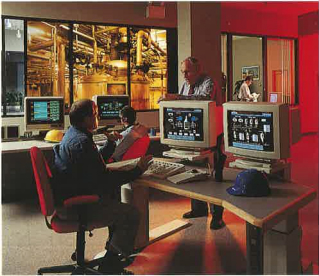

For example, one node in a network might be an Advant Station 500, a RISC. based workstation running AdvaCommand software in conjunction with SL-GMS. An operator at this station may watch a display modeling one stage in a chemical processing plant. When the appropriate symbol begins flashing, the operator uses a simple point-and-click mouse function to begin the next stage of processing – all in real-time.

Simultaneously, on another networked workstation, an engineer utilizing Advainform software and SL-GMS can review graphical displays of production statistics in order to optimize operations and the displays will constantly update themselves as adjustments are made.

The flexibility of SL-GMS allows this functionality to

be applied in a variety of industries. ABB has created a library of display elements, based upon the ISA standards for graphical display symbols. Once the system is installed and the customer’s personnel have received a few hours of training, they can create their own displays using the Display Builder to easily cut and paste

between graphics.

Also, palettes of colors, shades, patterns, basic objects and application-specific objects are available to developers. These make it easy to use such SL-GMS features as: increased object resolution, realistic shading and colors and mixed displays of text and graphics in displays. Further, developers can create displays that use the symbols and practices that are already familiar to operators in the user’s industry.

Finally, the SL-GMS high resolution graphics have helped ABB to create an ergonomic environment which enhances operator efficiency. Data from a variety of sources including programmable controllers, information management computers and analyzers is displayed on the same screen, reducing operator fatigue and increasing object recognition. However, the operator can change screens with a minimum of keystrokes using pull down menus and dialogue boxes. Since SL-GMS objects are dynamic, the operator receives a constant update (screens are refreshed once a second) without any operator action required.

The benefits of SL-GMS for ABB and its varied customer base center on its ease-of-use and flexibility. Plus, SL-GMS has helped make it a user-friendly system. It is a pre engineered, understandable system that allows users to operate the control system without high-level computer expertise. The ABB integration of SL-GMS software allows users to utilize their knowledge of their own business and apply inclust1y-specific symbols.

Through the AdvaCommand Display Builder, ABB has found that SL-GMS is easy to learn. A small group of ABB developers were trained initially and have been able to further train additional ABB personnel. Ongoing support requirements for SL-GMS are also minimal and easily supported world-wide from one office in Sweden.

Once installed, ABB’s customers find they are able to use SL-GMS development within hours of installation to create customized displays. Instances of the objects are copied to create displays that model tags, groups or processes. Consider the example of a new system at a power generation plant.

In that industry the color red is used to indicate a “power on” condition. In most industries ABB serves, the opposite is true. However, using the c1’evelopment tool, the user can assign color to an object with a few clicks, zoom in and out of detail work, or make the object dynamic. This makes it possible to customize clown to the individual operator requirements.

In the past, ABB sometimes found the cost of development of specialized displays prohibitive in some industries. Now, with SL-GMS, ABB offers a system that is flexible enough to meet the requirements of individual operators in virtually any inclustiy.

Advant and ABB-Master are registered trademarks and AduaCommand, AdvaBui/d, Advahiform and MOD 300 are trademarks of Asea Brown Boveri.

Switch to a smarter, more flexible and easy-to-use graphical modeling software.

Try SL-GMS