Flexible Integration Meets Diverse Customer Requirements

GE has found that the separation between SL-GMS and the applications programs provide maximum flexibility for the user installation. GE’s modular software design allows each user to select a different set of systems, one that meets the needs of that utility. If every object had to be created from scratch it would take months to model the processes at the plant. Instead, GE and the customer use the SL-GMS toolkit to copy objects from a standard library, including tanks, meters, gradients, graphs, lines, text and other graphic images. These can then be modified to fit the specific application, often within minutes, as opposed to the clays it took using previous generations of graphic display tools.

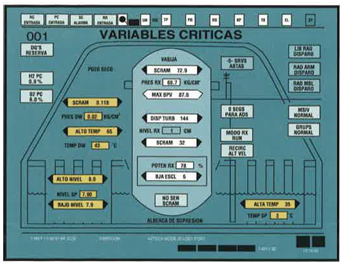

SL-GMS is flexible enough to allow the user to tailor the object to meet the plant’s operating parameters.

For example, the end-user can set or adjust the warning level on a process, without the need to take the system clown and recompile the application programs.

Teaming SL-GMS with X Windows ancl workstations, the operator can quickly click to various levels for displays of different processes. Or, the operator can determine the results of operational decisions implemented in previous windows.

SL-GMS provides the GE system with the capability to meet the requirements of the Nuclear Regulatory Commission’s (NRC) display/reporting. The NRC reporting requirements are very specific for each plant. SL-GMS is flexible enough for the operator to easily adjust the displays in order to meet the format requirements for information set by NRC.

The most important operating standard for a nuclear plant is safety. And yet, the plant must operate profitably. With the SL-GMS integration, the GE Nuclear Energy Division can provide high quality products at reduced cost to meet the business and operating requirements of its customers.